Ressources dossier

BioeconomyEnsuring sustainability

Published on 17 February 2023

To quantify a product’s myriad environmental impacts, life cycle analysis (LCA) is the method of choice.

Michael O’Donohue, head of INRAE’s Transform Division, explains, “For a biobased material to remain a carbon sink, it needs to be maintained in the technosphere” (see the glossary section). He continues, “When plant biomass is removed from the environment, there will be GHG emissions, local pollution, or negative effects on animal and plant biodiversity. Keeping a material in the technosphere means reusing it, limiting energy consumption, and reducing the need for additional biomass.”

To quantify a product’s myriad environmental impacts, life cycle analysis (LCA) is the method of choice and even comes with an international standard (ISO 14040). However, most often, a simplified form of LCA is carried out by private companies or publicly funded organisations. They calculate a single metric: the difference between the carbon stored and the carbon emitted by the creation of a product or service. Yet, as noted by Arnaud Hélias, a specialist in environmental assessments at the Joint Research Unit for Technologies and Methods for the Agriculture of Tomorrow (UMR ITAP) in Montpellier, “Simplification can be problematic because pollution may end up being transferred among impact categories. An action that improves one criterion may negatively affect a different criterion. For example, reducing pesticide levels means increasing tractor usage, leading to greater fossil fuel consumption and carbon emissions. Yet, fewer pesticides means fewer toxins in the environment and less stress on ecosystems. If you just look at a single criterion, you can end up with a false sense of reality.”

.

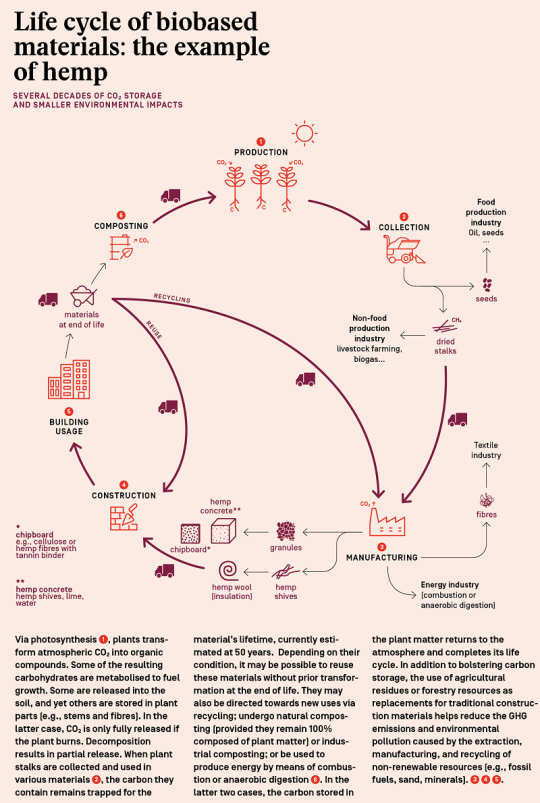

Analysing inbound and outbound flows

However, LCA truly shines when juggling multiple criteria. Indeed, as Arnaud Hélias explains, “At each production stage, LCA quantifies the environmental impacts of a given product or service taking into account its benefits.” The analysis scrutinises all the required incoming and outgoing flows, including energy resources, raw materials, and transportation. “For biobased materials, for example, the LCA begins with the impacts of producing the raw material in the field, manufacturing the fertiliser of choice, deploying the tractor in plots, and producing the fossil fuels burned. It also examines any sources of toxicity.” In 2006, INRAE performed an LCA for hemp concrete1. The findings showed that “a hemp concrete wall with a wood frame could act as a carbon sink for a 100-year period”. They also gave rise to two recommendations: that the crop’s nitrogen fertilisation regime be better managed to limit nitrite pollution in the water supply and that transportation be optimised because of its high cost and large carbon footprint. Indeed, the mean distance between farms and construction sites is nearly 1,000 km. Since the passage of the 2020 environmental regulations, CEREMA has begun to use LCA to produce safety data sheets for biobased materials. These standardised documents summarise the technical and environmental performance of different materials for construction companies. This is the first step in efforts to bring about large-scale transformations within the industry.

Click on the image to download the infographic in PDF.

Conducting regional analyses…

The LCA method has been adapted to regional scales to help ensure that economic and social development generates the smallest environmental impacts possible.

The problem is that these evaluations remain industry specific because they focus on defined products or services. Such an approach does not allow for a holistic perspective of environmental problems at higher levels. Researchers contributing to the ELSA-PACT Chair have adapted the LCA method to regional scales. The objective is to help ensure that economic and social development generates the smallest environmental impacts possible. The question arises: why the region? “We must work at the regional scale if we want to change production and consumption patterns.” Within regions, impacts and services are evaluated in relation to broader issues of concern (e.g., employment, transportation, energy consumption, water usage, land use). This approach can be used to create a regional map identifying the largest sources of pollution. Stakeholders can then develop impact-reduction scenarios whose environmental performance can be evaluated. The method also considers pollution produced outside of the region, which is often forgotten. Because this technique was only recently developed and remains expensive, it has yet to be widely used outside of research settings. However, it has given rise to specialised software for exploring water sharing: WASABI compares development scenarios to identify optimal water supply choices for a region.

…to build stronger bioeconomies

Other approaches aim to facilitate regional transitions. The Joint Research Unit for Agriculture and the Environment (UMR LAE) has established the MAELIA platform, which can estimate the quantity and distribution of agricultural biomass using land use, climate, and plant growth data. Estimates can be generated at both the plot and region level. “We can model crop planting, harvesting, and daily fate for 50 years across nearly 8,000 plots,” says Julie Wolfahrt, a researcher in the unit who specialises in multicriteria evaluations. It is possible to model farming practices (e.g., ploughing regime, phytosanitary treatments, irrigation schemes) and their environmental impacts within plots.

The consulting firm MAELAB3 has made the platform available to regional stakeholders, including local authorities. The latter have been using MAELIA to guide them in their bioeconomic decisions.

Designing and evaluating construction projects

At present, the unit is trying to adapt MAELIA to function in other relevant industries: bioplastics, biobased construction materials, straw production, and wood production. Julie Wohlfahrt elaborates, “The eventual goal is to model all the uses of a given region’s biomass so that decision making can be informed by the interactions between urban and rural areas. For example: under what conditions will it be possible to build 100% biobased buildings in Greater Reims? Is this scenario realistic given nearby supplies of agricultural and forestry resources? What would the consequences be for established industries, such as those producing hemp textiles or wood pellets? How can we ensure that materials return to local fields at the end of life as composted fertiliser? Finally, in these new industries, what GHG emissions should we expect to arise from material transport or manufacturing?” Answers should be forthcoming in 2028. Greater Reims is among the six French regions chosen to participate in FairCarboN’s pilot project on scenarios for developing sustainable regional bioeconomies. This work was launched in April 2022 and has received 40 million euros in national acceleration strategy (PEPR) funds through France 2030, the government’s major investment plan. Jointly managed by INRAE and CNRS, FairCarboN will spend the next six years developing reasonable approaches, based on realistic assessments of agricultural and forest ecosystems, for mitigating the effects of climate change at local and global levels.

-

Sarah-Louise Filleux

(Send email)

Author / Translated by Jessica Pearce